Technologies & solutionsExperience is still the best expertise.

Direct evaporation systems

Cost-saving direct evaporation systems – efficient air cooling

In all applications in which large fresh or recirculating air flows are cooled, we offer you the advantages of direct evaporation technology.

This involves direct cooling of the air through the evaporating refrigerant in the cooling coil – an intermediate medium such as chilled water is not required. You benefit from significantly better energy efficiency compared to conventional cooling systems. Additionally, the investment costs for complex cold-water piping including pumps and control groups are eliminated.

.

Features

What our solutions have in common:

flexibility, efficiency and sustainability

Up to 40% lower

energy consumption

through direct air cooling without an intermediate medium

Turnkey

refrigeration system

including cooling coil, piping and commissioning

Highest

control accuracy

by stepless power control

Optional

heat recovery

of the available waste heat from cooling process

Keyfacts

We optimize customer benefits through

comprehensive measures:

Reduction of trade interfaces

through turnkey supply of the complete cooling system –including refrigeration machine, pipework, cooling coil and control technology

Small footprint and flexible installation

due to compact design and variable layout – ideal for decentralized retrofitting on existing installations

Complete elimination of cold water technology

i.e. cold water generation, piping including insulation, buffer tanks / switches, primary and secondary pumps, cold water control groups and coils and frost protection measures are not required

Reduction of investment and maintenance costs

by setting up combined systems for connecting several cooling coils with independent power control to one system

Individual plant configuration

e.g. for indoor or outdoor installation, in compact or split design, air- or water-cooled, modular design, redundant / multi-circuit design, sound insulation

Consideration of customer specifications

such as mechanical / electrical factory specifications, manufacturer specifications, special control cabinet equipment, communication interfaces, safety devices, etc.

Applications

Areas of application of our direct evaporation systems include:

Air conditioning of fully automated paint shops

Production cooling in the food industry

Warehouse cooling in the pharmaceutical industry

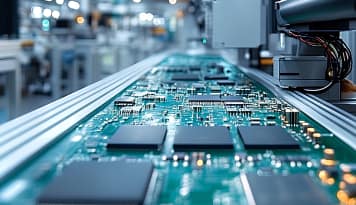

Cooling of electronics manufacturing plants

Air conditioning of shopping

centres

Comfort air conditioning for terminals

References direct evaporation systems

Reliable and multifunctional technology – successful in every application

Since 1979 we have been working with our global customers from a wide range of industries to find cost- and energy-saving solutions of the highest quality.